Author

Creative Director

Published

December 19th, 2024

Length

6 Minutes

When it comes to sustainable packaging, these are the two most pressing questions on the minds of today’s brand managers, packaging buyers, and supply chain professionals. Luxury retailers, boutique brands, and global fashion houses alike are striving to reduce their environmental footprint, optimize costs, and meet growing consumer demand for eco-conscious choices. But where to start?

In this article, we’ll dive deep into the most sustainable packaging materials and highlight which ones pose the greatest challenges to recyclability. Finally, we’ll introduce a paradigm-shifting approach— Design for Absence (DFA) —that can redefine how we think about packaging altogether.

Which Packaging Material is Most Sustainable?

Sustainability isn’t just about recycling; it’s about choosing materials with lower carbon footprints, sourcing renewable resources, and designing packaging that’s easier to reuse or break down. Ultimately, the “most sustainable” option depends on your product’s requirements, brand positioning, and the resources available in your supply chain. Still, some materials consistently rise to the top:

1. Paper and Cardboard

Pros:

- Sourced from renewable materials.

- Widely recyclable in most communities.

- Generally biodegradable

Cons:

- Requires substantial energy, water, and forestry resources.

- Not ideal for moisture-heavy products without additional coatings.

Best Use:

Dry goods, secondary packaging solutions, and product categories where customers expect a clean, natural look. Ideal for brands aiming to project an earthy, minimalist aesthetic.

2. Glass

Pros:

- Infinitely recyclable without loss of quality.

- Sourced from abundant raw materials like sand.

Cons:

- Heavy and fragile, increasing transportation costs and emissions.

- High energy consumption during initial production.

Best Use:

Luxury fragrances, premium beverages, and high-end cosmetics. Glass’s perceived value and aesthetic fit well with upscale, heritage brands committed to both elegance and eco-responsibility.

3. Aluminum

Pros:

- Highly recyclable with relatively low energy requirements once in the circular loop.

- Lightweight and durable.

Cons:

- Extracting virgin aluminum (from bauxite) can be environmentally intensive.

- Requires a strong recycling infrastructure to maximize efficiency.

Best Use:

Beverage cans, certain skincare products, and selective food packaging where an airtight, light barrier is essential.

4. Bioplastics (PLA, PHA)

Pros:

- Derived from renewable resources like cornstarch.

- Potentially compostable in industrial composting facilities.

Cons:

- Limited composting infrastructure in many regions.

- Often require specific conditions to break down properly.

Best Use:

Single-use cups, utensils, or liners in markets with established composting systems and consumers aware of proper disposal methods.

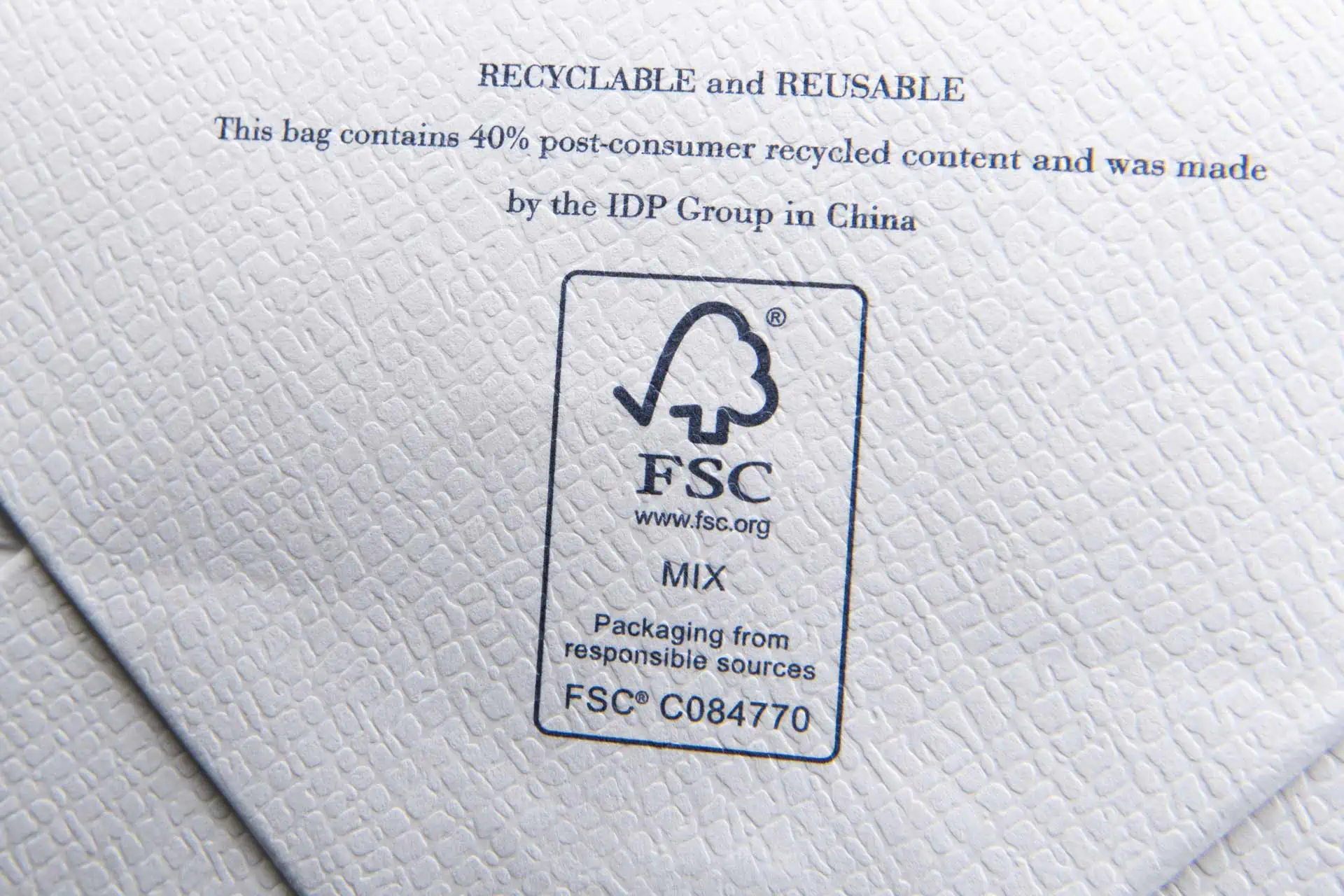

5. Materials and Recycled Content

Pros:

- Reduce the need for virgin materials.

- Lower overall carbon emissions by closing the loop.

Cons:

- May have variances in appearance or strength.

- Requires consistent supply of post-consumer material.

Best Use:

A great fit as a blended option into paperboard, plastics, or aluminum products, adding a layer of eco-credibility without sacrificing performance.

Takeaway

Choosing the most sustainable packaging material is not a one-size-fits-all proposition. Align your choice with your brand values, product requirements, and the recycling infrastructure of your target markets. Seek guidance from sustainable packaging experts who can blend material science with strategic design, ensuring your packaging stands out on shelves while meeting environmental goals.

What Packaging Material Is Not Recyclable?

Just as important as identifying the best materials is knowing which are least likely to be recycled. Some packaging formats, due to their mixed compositions or contamination issues, pose significant recycling challenges. Minimizing or avoiding these altogether can improve your brand’s green profile.

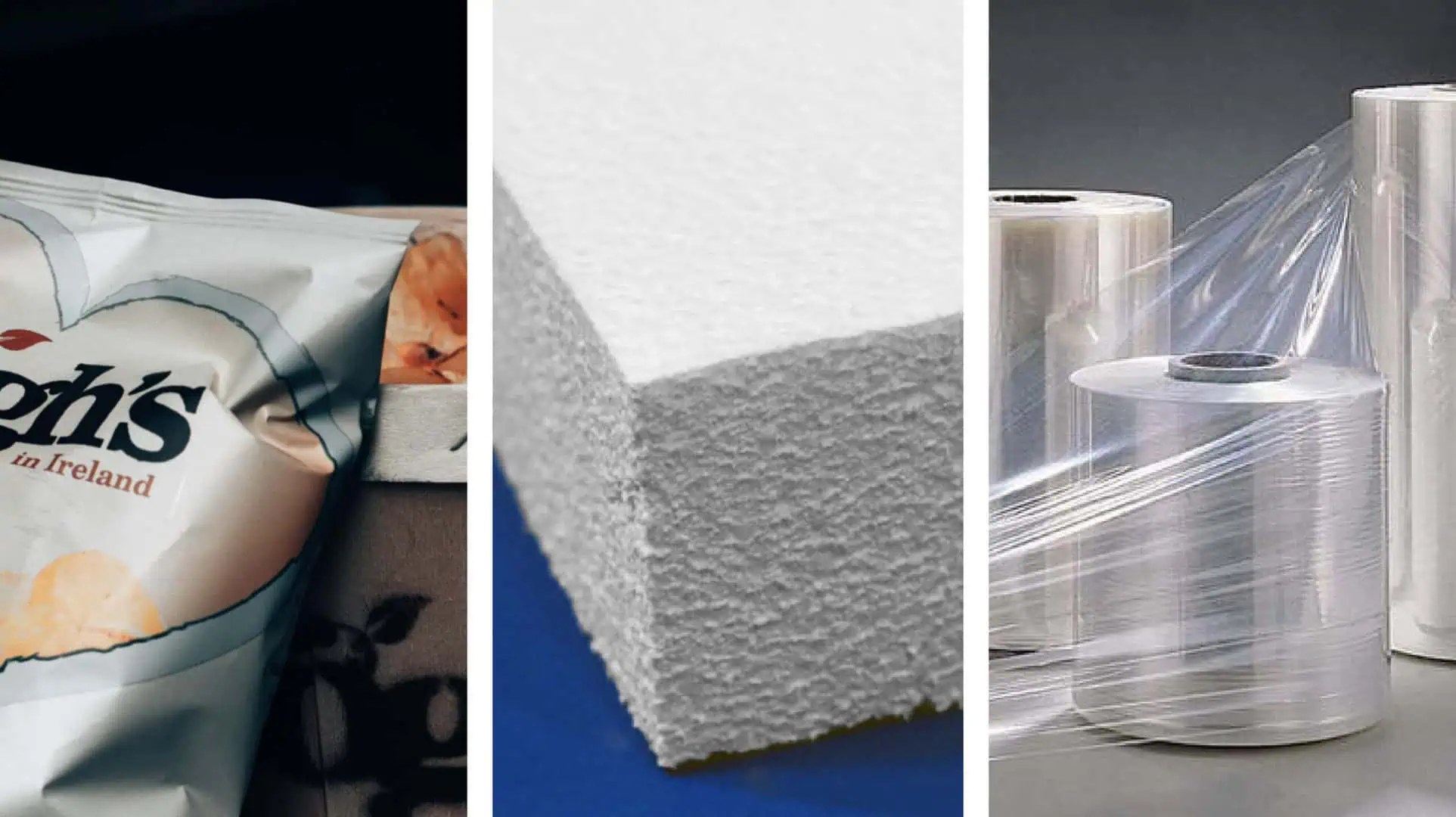

1. Multi-Material Laminates

- Examples: Snack pouches, chip bags, certain coffee bags.

Why Not Recyclable:

These are composed of multiple layers—plastic, aluminum, paper—that are fused together. Standard recycling facilities struggle to separate these layers, rendering them non-recyclable in most areas.

2. Polystyrene (Styrofoam)

- Examples: Takeout containers, protective foam inserts.

Why Not Recyclable:

Lightweight and bulky, polystyrene is notoriously difficult to recycle due to the limited economic viability and lack of curbside acceptance.

3. PVC (Polyvinyl Chloride)

- Examples: Some clamshells, shrink wraps.

Why Not Recyclable:

PVC often contains additives and releases harmful chemicals when processed. Many curbside programs simply cannot accept it.

4. Plastic Bags and Films

- Examples: Grocery bags, thin plastic wraps, bubble wrap.

Why Not Recyclable:

They can clog recycling machinery and require specialized drop-off points. Most standard recycling streams don’t accept them.

5. Wax-Coated Paper

- Examples: Certain food wraps, produce boxes.

Why Not Recyclable:

The waxy coating complicates the pulping process, making these materials unsuitable for standard paper recycling streams.

6. Contaminated Packaging

- Examples: Pizza boxes soaked in grease, containers with food residue.

Why Not Recyclable:

Contamination disrupts the recycling process, reducing the quality of recycled fibers and necessitating disposal instead of recycling.

How To Avoid Non-Recyclable Packaging

- Opt for mono-material solutions whenever possible.

- Educate consumers on proper disposal.

- Collaborate with suppliers to explore alternative materials or innovative recycling techniques.

For brands, steering clear of non-recyclable packaging conveys a strong sustainability message—showing customers you care about the entire lifecycle of your product, not just the initial purchase.

Rethinking the Problem: DFA (Design for Absence)

Now that we’ve answered the two core questions—“Which packaging material is most sustainable?” and “Which packaging material is not recyclable?”—it’s time to challenge the very premise of these inquiries. What if you could skip asking these questions altogether by minimizing or even eliminating packaging right from the start?

Design for Absence (DFA) is an innovative approach that goes beyond simply choosing better materials. It fundamentally rethinks packaging design with the goal of eliminating unnecessary components before they even reach the production stage. Instead of focusing solely on material composition, DFA asks: Do we need this packaging at all?

How DFA Works

- Product-Centric Approach: By integrating branding elements directly onto the product or using the product’s inherent structure for protection, DFA reduces the reliance on outer boxes and fillers.

- Supply Chain Optimization: Every gram of material saved is a win for the environment and the bottom line. DFA streamlines design to minimize packaging weight, trim waste, and cut down on shipping emissions.

- Enhanced Consumer Experience: Today’s consumers value simplicity and sustainability. DFA delivers both by reducing clutter, improving unboxing experiences, and showing that your brand values responsibility and innovation.

Why Embrace DFA?

- Environmental Gains: Less material means fewer resources and lower carbon footprints.

- Cost Efficiencies: Reduced packaging equates to reduced costs—fewer raw materials, lighter shipments, and leaner logistics.

- Brand Differentiation: In a crowded marketplace, DFA sets you apart as a forward-thinking, sustainability-led brand.

Final Thoughts: Taking Action Toward a Greener Future

Answering the big questions—Which Packaging Material is Most Sustainable? and Which Packaging Material is Not Recyclable?—helps set the stage for more informed decisions. But true innovation comes from reimagining the role of packaging itself. By embracing DFA, brands can eliminate the question of recyclability at its roots, leading to packaging strategies that are inherently more sustainable, cost-effective, and appealing.

Your next move? Bring these insights into your planning process. Consider partnering with experts who understand material science, regulatory landscapes, and consumer psychology. At IDP Direct, we specialize in guiding luxury and premium brands toward smarter, greener packaging solutions, whether that means selecting the most sustainable materials, avoiding the pitfalls of non-recyclable formats, or taking a bold leap into DFA.

Ready to make a change?

Contact us at info@idpdirect.com to explore how you can rethink your packaging strategies, align with consumer values, and build a more sustainable future for your brand.