Author

Logistic Specialist

Published

August 26th, 2024

Length

3 Minutes

At 29, Julie Walker made a decision she thought was routine.

She was sourcing packaging from a reseller. Now, she’s facing tough questions from her finance team about the 25% tariff on imports from China.

It was June 2024, and the luxury market was already under pressure. Julie, like many buyers, assumed sticking with Chinese suppliers was just part of the game. But as consumer spending slowed and costs rose, that decision has come under scrutiny—leaving Julie to justify why her brand is paying significantly more when other options exist.

The Shift from Legacy Knowledge to Modern Practices

In the wake of the post-COVID transition to remote work, countless legacy employees—who held invaluable knowledge of pre-tariff business practices—left their positions.

Meanwhile, a new generation of buyers stepped in, armed with fresh skills but perhaps less aware of the historical context of their decisions. For many of them, the 25% tariffs on Chinese imports became an accepted cost of doing business, a line item on a spreadsheet rather than a red flag.

This shift in the workforce may have led to a complacency that allows these tariffs to persist without challenge, raising the question: Are modern practices unknowingly costing brands millions?

A Market Slowdown Calls for Cost Efficiency

As consumer spending tightens, brands continue to be under the microscope, scrutinizing every expense to protect margins without compromising quality.

In the U.S. market, where spending is currently on the upswing of a rollercoaster ride, the economic pressures are palpable. With China’s rising labor costs and a 25% tariff that’s driving prices sky-high, clinging to Chinese manufacturing is a costly gamble.

Now more than ever, brands have an opportunity to reassess their packaging strategies, exploring smarter, more cost-effective alternatives that don’t just preserve quality—they enhance it.

Seeking a Strategic Advantage

The China Tariff Trap has ensnared countless brands, quietly siphoning off profits as they continue to pay a 25% premium on packaging imports. This hidden cost has become an accepted burden, yet it’s one that brands don’t need to bear.

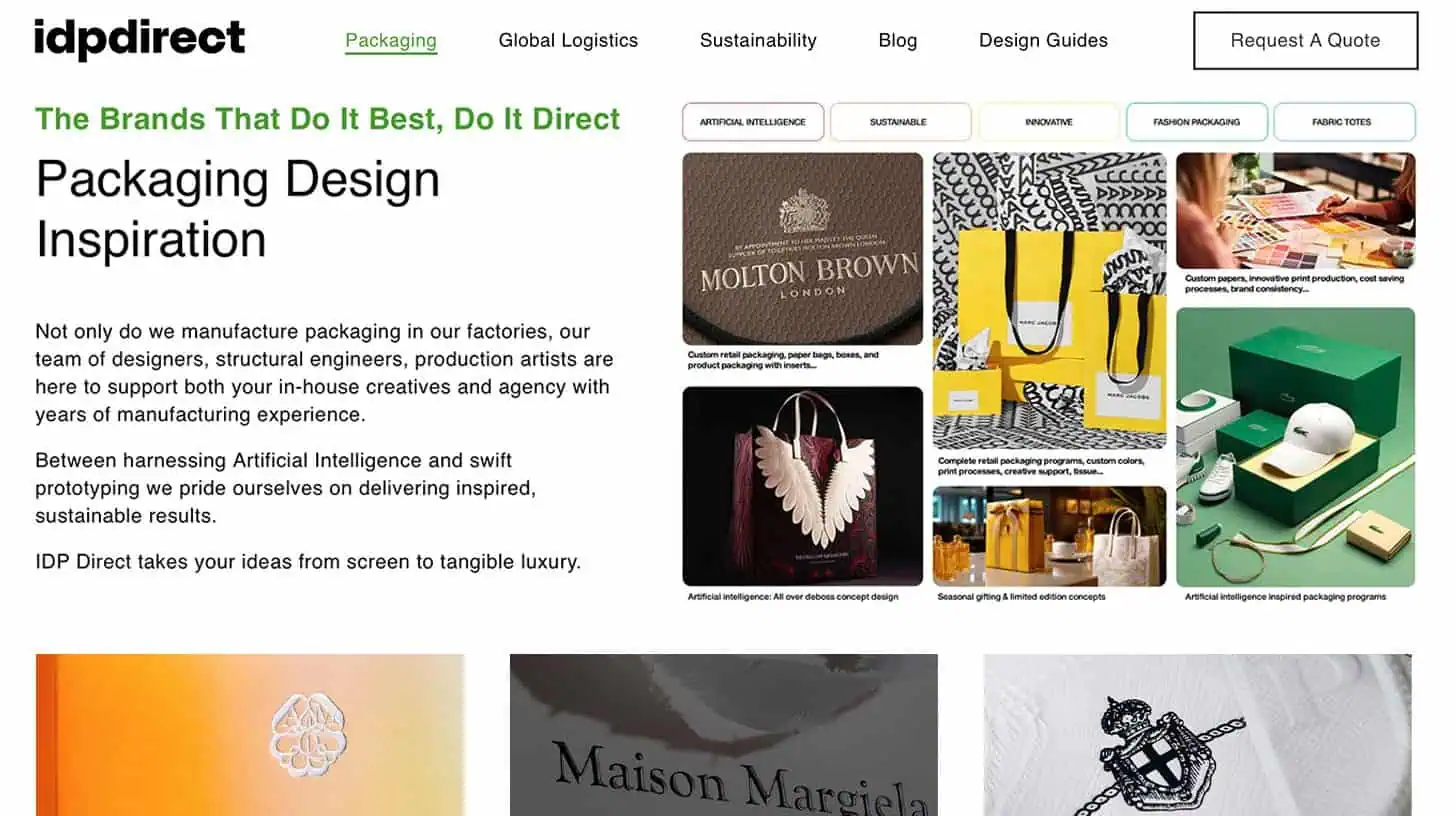

Enter IDP Direct, a growing force helping U.S. brands break free from this costly cycle.

By manufacturing packaging in Mexico, Indonesia, and Romania, IDP Direct bypasses the tariffs entirely, offering a clear and effective solution.

Owning our factories from the ground up, we eliminate middlemen, inflated reseller margins, and deliver beautiful packaging directly to brands.

For those ready to escape the China Tariff Trap, we might be the simplest answer to a complex issue, helping brands maintain—if not enhance—their standards without the unnecessary financial strain.

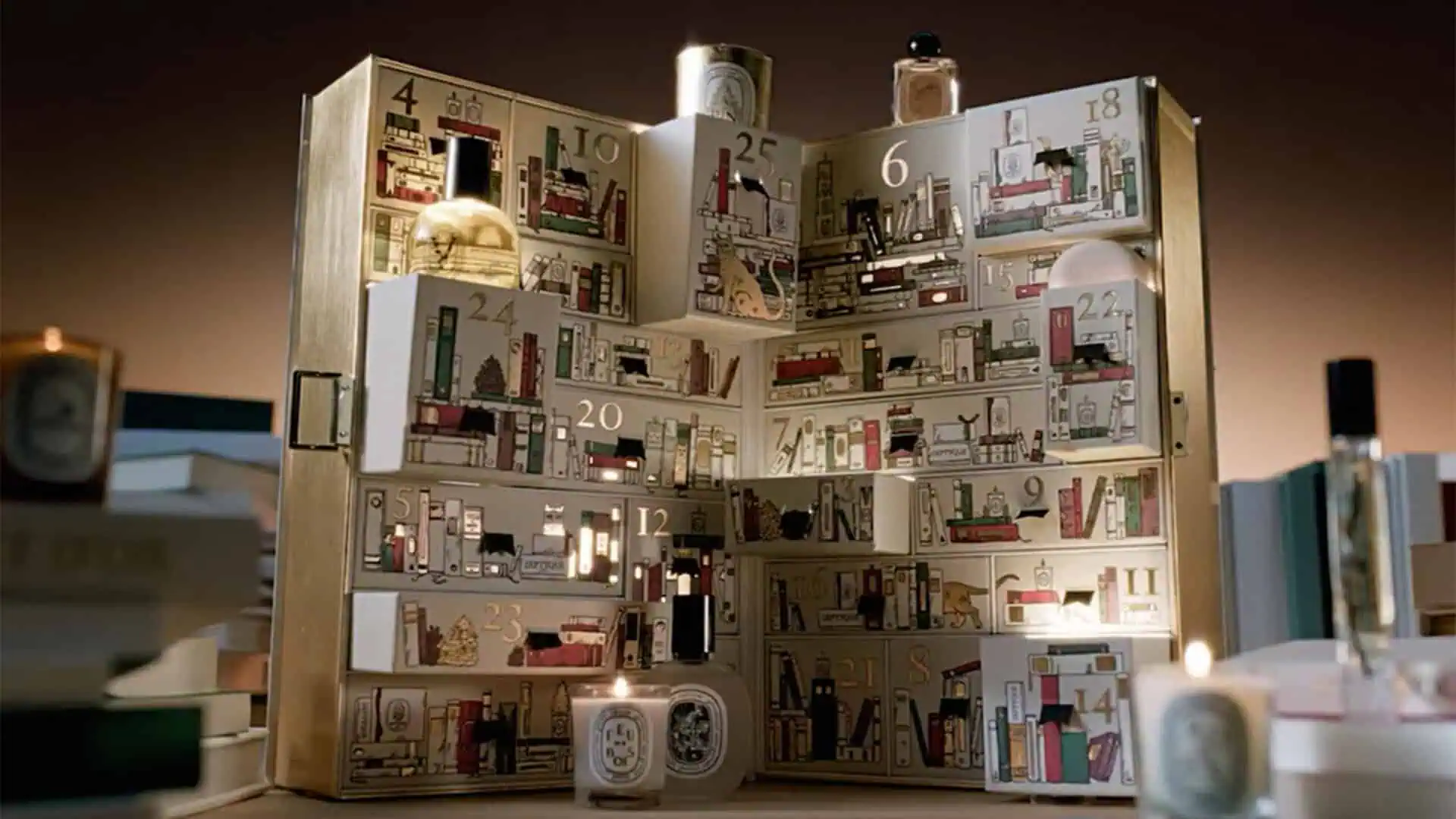

Our latest China duty-free packaging for Lilly Pulitzer

Sustainability isn’t easy.

And slaying it is even harder.

The latest Lilly Pulitzer packaging evolution is nothing short of a revolution, reflecting their unwavering commitment to both style and sustainability. The brand, known for its iconic hand-painted patterns, neon inks, and playful nods to its founder, has always been at the forefront of packaging design. But now, they’ve taken a bold step forward, bidding farewell to the days of plastic-laden collectable totes and ushering in a new era of eco-chic innovation.